The Main Principles Of Spandrel Panel Window

Table of ContentsHow Spandrel Panel Definition can Save You Time, Stress, and Money.Facts About Spandrel Panel Detail RevealedThe Ultimate Guide To Spandrel Panel DefinitionSpandrel Insulation Fundamentals Explained

Whether you require Glazing Infill Panels, Spandrel Panels, Darkness Boxes, Soffits, Copings, Backpans or Flashings, Embury Company will provide on time as well as on budget. Let our team aid and guide you through every one of you metal panel requirements. Our State of the Art Facilities permits us to function flawlessly with any kind of sort of product and obtain you what you need.

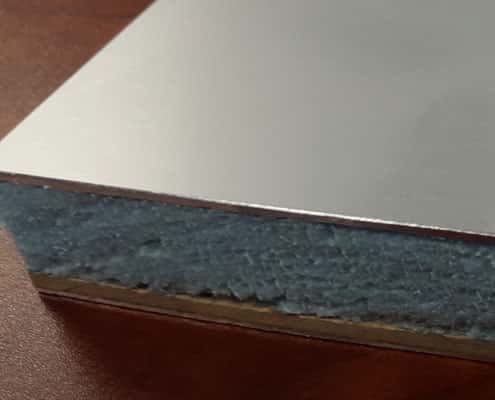

The panels are available from.016 to 3/16 (.1875) of an inch, making use of Light weight aluminum, Stainless Steel, Galvanized or ACM. Whatever the thickness, product or coating Emburite Panels will answer the requirement.

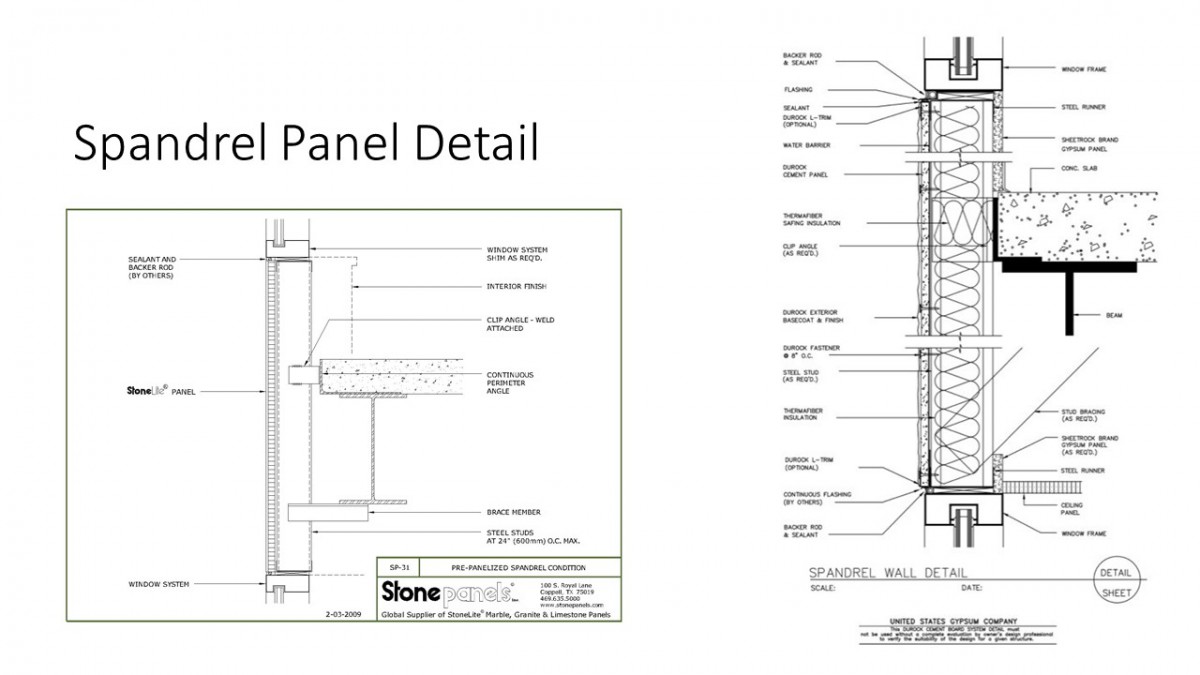

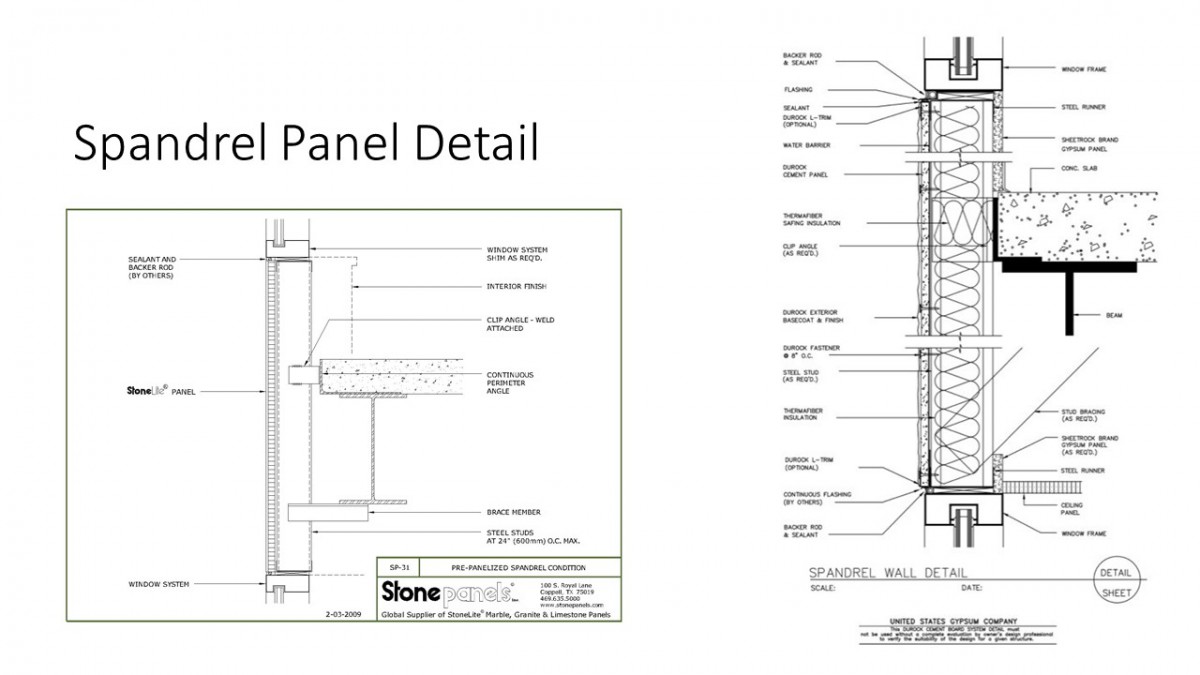

The very first significant example of the design was the Equitable Savings & Finance Structure in Rose city, Oregon carried out by engineer Pietro Belluschi in 1948. As the world's very first fully confined cool structure, this streamlined 12-story structure quickly established the pattern for numerous post-WWII skyscrapers and tiny scale office buildings. The curtain wall system is comprised of a recurring grid of upright extruded light weight aluminum mullions as well as horizontal rails.

Facts About Spandrel Panels Cladding Timber Uncovered

These spandrel panels can be available in a range of products. Early spandrel panels were made from heat-strengthened nontransparent glass integrated with colored ceramic. The Pittsburg Plate Glass Firm produced the glass panels under the brand name "Spandrelite," and used 8 typical shades. The Libbey-Owens-Ford Corporation marketed sixteen shades alternatives under the "Vitrolux" brand name.

Thought about suitable for practically any dimension commercial, government or institutional building, the Curtain Wall surface style ended up being extensive by the very early 1950s. Lots of post-WWII structures of differing styles likewise included drape wall systems into some exteriors however are ruled out Drape Wall design unless most of the noticeable exteriors are so constructed.

Thus, lightweight products can be used in their growth. Business glazing systems are normally built of aluminum-framed walls with glass, metal panels, louvers, operable home windows or vents, or rock veneer infills. Structure envelope consultants will certainly commonly encourage developers on curtain wall as well as store front demands for constructing movement, thermal development as well as contraction, water diversion, and thermal efficiency.

Some Known Incorrect Statements About Spandrel Panel

Condensation development on spandrel infill is most likely to occur during severe winter season problems when inadequate warm is supplied from the interior to avoid indoor infill surface area temperature levels from continuing to be over the dew point. When interior surface area temperatures dip listed below the dew point, water molecules begin to base on the indoor surface of the spandrel infill.

Should poorly designed spandrel problems be left unattended, condensation can result in dampness or visual damage to the spandrel panel and/or indoor surfaces. When condensation types at the spandrel infill of a glazing system, several kinds of damage can happen, and also the effects of condensation can go to the website be significant. Along with moisture damage as well as microbial growth, condensation growth on spandrel infill can additionally have an unfavorable impact (spandrel panels cladding timber).

One means to delay the development of condensation on the glazing system spandrel infill is to make use of the structure HEATING AND COOLING system. By enhancing air movement near these locations, even more heat will be transferred to the setting up and also increase indoor surface temperature levels. One more means to utilize the HVAC system is by reducing the inside loved one humidity set points relative to outside temperature level.

An additional method of preventing condensation is by securing the horizontal-to-vertical mullion joints at the spandrel cavity to avoid unrestrained air movement right into the dental caries. Commonly, an unrestrained interior is moisture laden and also when his explanation it comes into call with the spandrel infill, which is listed below the humidity, it enhances the amount of condensation formation.

Getting My Spandrel Panel Window To Work

In enhancement to including rehabilitation technique, means to reduce condensation capacity throughout design consist of: Normally drape wall systems have higher resistance to condensation than shop systems. Using drape wall is one means to reduce, or postpone the start of condensation formation. At Pie, we provide 2-D thermal modeling (THERM) to assist our customers with the style of spandrel areas.

By knowing surface temperatures, Pie has the ability to determine under which problems condensation will take place, along with identify shift factors at which condensation will not create, making it much easier to anticipate and remediate. On top of that, different setups can be designed to maximize indoor surface area temperatures. Setting up back pans right into the spandrel infill glazing pocket, which are aired vent to the outside with insulation outboard of the pan, advertises enhanced interior surface area temperatures with the added benefit of decreasing warm transfer through the spandrel infill.